Quick favor: If you like this edition, forward it to one person who builds real things. It helps us grow. 💪

Welcome to Issue #009 of Neural Newton

This one’s a torque wrench to the temple. Neural Concept bags $100M to turn CAD into a speed-run, Amazon rolls an agentic warehouse brain with multi-arm robots, and Quilter’s AI designs a 843-part Linux SBC and boots it first try just to make PCB teams spit coffee. Meanwhile Hexagon ships an urban twin that actually leaves PowerPoint, and Kargo raises big to make docks see like cyborgs while Menlo says enterprises are buying outcomes, not frameworks.

On the data spine, we’re wiring geometry, QA, and sensor exhaust into models that understand meshes, GD&T, and takt - so copilots stop hallucinating burrs and start shaving hours. In the tool crib, Augmented Industries, CERPRO QualiSpec, and HOOPS AI show up with gear that respects torque specs and inspection plans. The rumor mill says CAM teams are quietly trialing constraint-aware toolpath copilots, and a Tier-1 is teaching an LLM to read tolerance stacks without crying.

We close with the money trail (it’s real), a shop-floor rant (also real), and a baseball-bat-to-ego clip courtesy of Quilter’s PCB mic drop. Strap in.

🏭 The Retrofit: Neural Concept’s $100M says “AI is now a design partner, not a toolbar”

Goldman doesn’t toss nine figures at vaporware. Swiss startup Neural Concept just closed a $100M Series C led by Growth Equity at Goldman Sachs Alternatives to scale what they call “AI-native engineering.”

Translation: their models read your actual 3D geometry, learn from your historical CAE, and then predict performance + propose design variants in seconds, directly in the engineering loop, not as a chat bubble on the side. If you’ve ever watched a late-stage aero change nuke your tooling calendar, this is the antidote. Neural Concept+2Yahoo Finance+2

Why this is different from the usual “copilot for PowerPoint”: Neural Concept treats geometry and physics as first-class citizens. It plugs into CAD/CAE stacks and reasons over meshes/parametrics instead of dumping PDFs into an LLM and hoping for the best. Their customers span auto, aero, energy - and the pitch is blunt: fewer redesign cycles, fewer week-12 “gotchas,” more first-time-right. SiliconANGLE

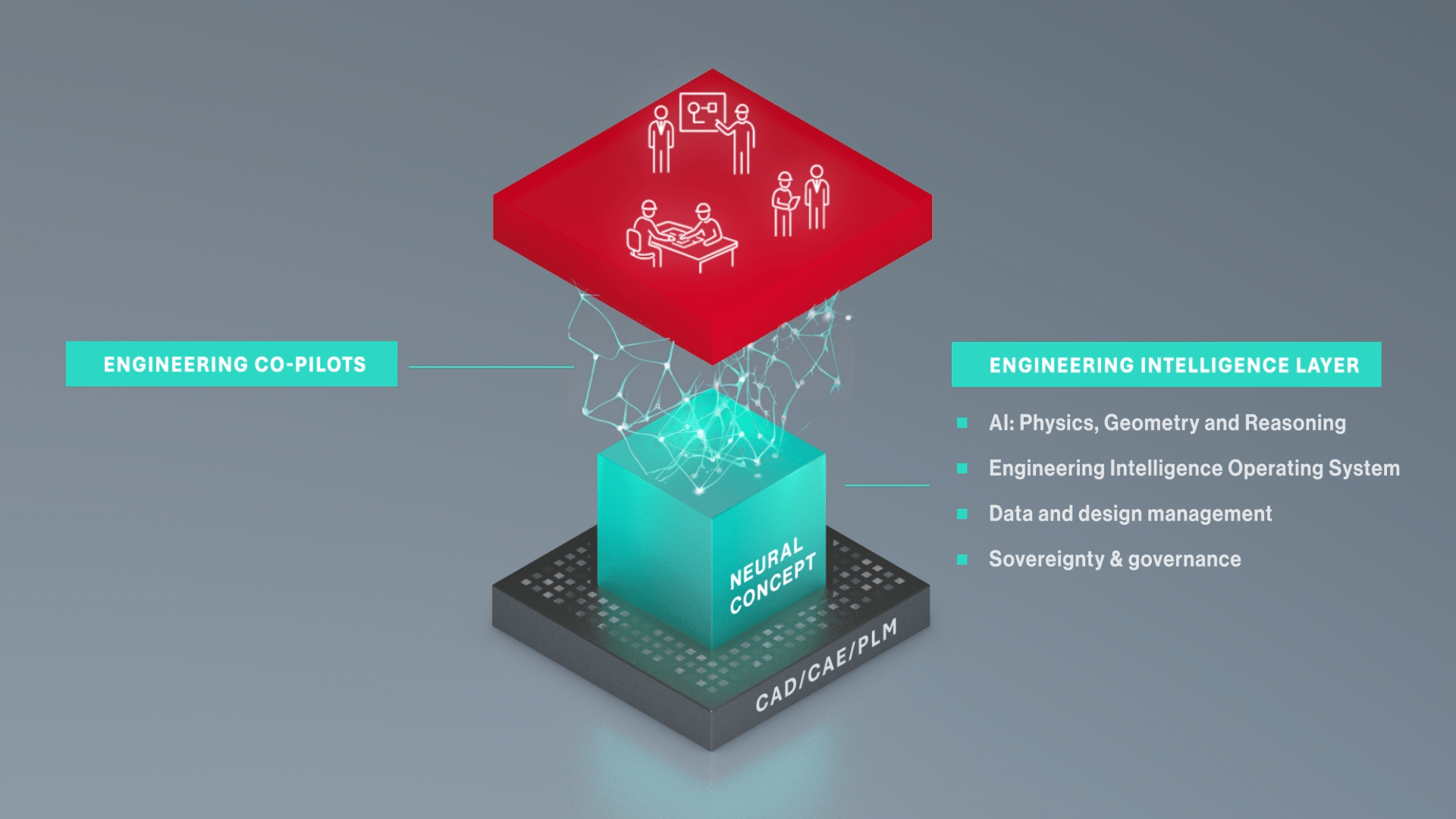

The meta-signal: capital is pivoting from horizontal chat to domain-trained models that own engineering representations (surfaces, tolerances, meshes) and automate design exploration. Think “engineering intelligence layer” that sits on top of CAD/PLM and tells you what to try next - then validates it. If this round accelerates integrations with the usual big-iron toolchains, expect the average design review to swap 30 slides for 3 candidate geometries and a probability band. (And yes, the meetings will still run an hour.) Neural Concept

Moral for real engineers: Don’t wait for a vendor keynote to bless this. Start curating your simulation data, tag your geometry with the metrics you actually care about, and pilot on a high-iteration subsystem (ducts, housings, impellers). If the model beats your baseline on iteration speed and late-change rate, you’ve just bought back a quarter.

⚙️ Gearbox: Rapid News Roundup

Quilter’s AI designs a Linux SBC (843 parts) in ~38.5 hours; boots first try. Hardware folks felt that in their wrists. Execution phase just got compressed. Tom's Hardware+1

Menlo Ventures: enterprises now buy, not build - AI app spend dominates 2025. Domain apps are eating the budget line. Good luck to DIY skunkworks. Menlo Ventures+1

Amazon rolls out Blue Jay (multi-arm robot) + Project Eluna (agentic ops AI) + smart glasses. Same-day sites are the testbed; fewer touchpoints, faster picks, less reaching. Supply Chain Dive

Hexagon’s “ZugTwin” goes live. Urban-scale twin now a productized reality in Switzerland; cue more municipal + plant-adjacent twins. Hexagon Geospatial Blog

ARM Institute funds new robotics/AI projects (~$4M total contribution). Small dollars, big leverage for deployable shop-floor tech. ARM Institute

📐 Blueprints IRL: Amazon’s agentic warehouse - fewer stations, faster flow

Problem: Same-day fulfillment wants throughput without extra square footage or repetitive-motion injuries. Classic stations (pick → stow → consolidate) multiply handling and slow the line.

AI approach: Blue Jay collapses those stations by coordinating multiple robotic arms at one workspace; Project Eluna acts like an ops co-pilot - reasoning over real-time + historical signals to anticipate bottlenecks and nudge decisions; smart glasses keep delivery data in the driver’s sightline. Supply Chain Dive

Result: Early deployments emphasize less reaching/lifting, fewer hand-offs, and faster exception handling. Media briefings point to ~75% of item types handled at test sites and an emphasis on same-day networks - while the glasses trials focus on hands-free scanning, directions, hazards. Supply Chain Dive+1

Takeaway: This is not “robots took my job;” it’s “robots took my third walk across the cell.” The interesting part is Eluna’s agentic control - when the planner isn’t the human or the PLC, but a reasoning layer that juggles constraints at line speed. Your brownfield site doesn’t need a metaverse; it needs one fewer station and one smarter brain. Supply Chain Dive

🔥 Signal Drop: The hype pivot: from “chatting with PDFs” to “optimizing geometry and takt”

If 2023 was “ask a bot,” and 2024 was “integrate a bot,” then late-2025 is “embed a model that knows your units, tolerances, and cycle time.” The winning startups aren’t writing essays; they’re reading CAD, QA drawings, PLC tags, and sensor time-series - and moving levers (layouts, setpoints, toolpaths). Capital is voting accordingly: Neural Concept in design, Kargo at the dock, and a parade of agentic “ops brains” on the floor. The lesson is painfully simple: if your AI can’t speak step, mesh, GD&T, or SKU, it can’t speak production. Mic drop: if your “digital twin” is a slide, you built a ghost factory. Neural Concept+1

🛠️ Toolbench: Three actually-useful new tools

Augmented Industries (Flow Tool) → Captures tacit tech knowledge, autogenerates procedures, speeds onboarding on real lines. Finally, a “copilot” that knows what a torque spec is. Engineering at Cambridge+1

CERPRO QualiSpec → Parses drawings, auto-builds inspection plans in minutes. Turns QA from “Where’s the ballooned PDF?” into “Here’s the plan.” Tech Funding News+1

Tech Soft 3D HOOPS AI → Bridges raw CAD data to ML datasets for custom model training. Because your geometry shouldn’t need a 3-week ETL cleanse. Metrology News

🕵️ Shop Floor Rumors

Constraint-aware CAM copilots are in stealth at two U.S. machine-tool OEMs - think toolpath agents that honor fixturing, stock, and machine limits without babysitting. (Investor decks are making the rounds.)

GD&T-literate LLMs trained on internal drawings + NCRs are outperforming generic models on tolerance stack questions at an auto Tier-1 pilot. (No public results yet - only NDA bragging.)

💰 Grease Money - Follow the chips, clips, and clips (of wire)

Neural Concept nabbed $100M Series C (Goldman Sachs Alternatives), fueling AI-native design across auto/aero/energy. Signal: design intelligence is now a budget line, not a hackathon. Neural Concept+1

Kargo raised $42M Series B to scale AI + edge-sensing towers at docks; customers reportedly up from 3 → 45 while overall supply-chain VC slumped to $7.8B this year. Proof you can grow in a down sector if your models see pallets, not prompts. Wall Street Journal

Enterprise AI spend: Menlo pegs $37B this year, with apps (not infra) capturing the majority - and copilots a big bite. Procurement has spoken: ship outcomes, not frameworks. Yahoo Finance

CFO view: 2026 budgets will cut “AI exploration” but increase line items with hard ROI (hours saved, changes avoided, throughput unlocked). The AI tourist traps are closing; the factories are open.

🧑🏭 Machine Whisperer: Pierre Baqué (Neural Concept CEO)

The EPFL-trained founder just put industrial AI squarely in the design loop. His line this week: advances in AI are turning engineering from trial-and-error into a “data-driven workflow” where tradeoffs are optimized up front.

Why he matters: he’s dragging AI from chat panes into geometry-native decisions - which is where money is lost or saved. Watch his team’s CAD/CAE integrations; that’s the adoption choke point. SpaceWar

🧠 Dumb Things Smart People Will Say in the AI Era

“Our digital twin is 100% deployed right after the board approves the color palette.”

“The robot didn’t replace anyone; it just made everyone else optional.”

“We don’t have a tolerance problem - the AI hallucinated the burrs.”

“Procurement says the copilot needs three quotes and a wet signature.”

🧊 Coolant Break: A computer in a week? AI shrugged and shipped.

Quilter’s AI designed a dual-PCB Linux box with 843 components in roughly a workweek and booted Debian first try. Minimal human hours, maximum engineering indigestion. If your PCB flow still feels like pouring molasses uphill, consider this your calendar invite to 2026. Tom's Hardware+1

That’s it for Edition 9.